Discover how CARBOFLEX can improve carbon control for consistent result in carburizing, annealing and hardening

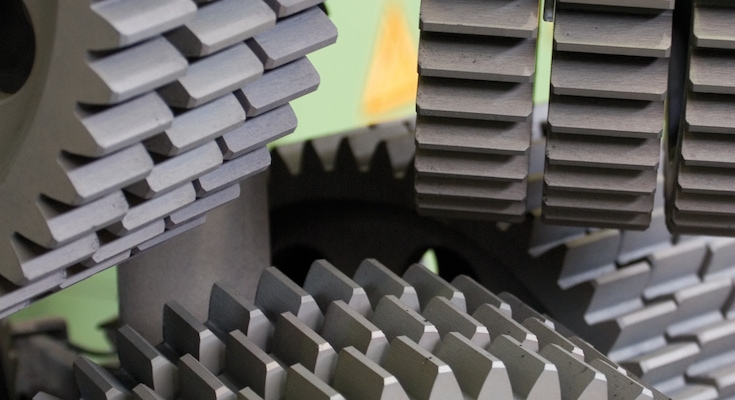

Various semi-finished products and components with stringent quality standards must be treated in controlled furnace atmospheres to avoid oxidation, decarburization and similar effects. These controlled furnace atmospheres serve two fundamentally different purposes. On the one hand, thermal processes such as annealing and hardening require a neutral atmosphere to protect the metal surface. And on the other, thermochemical processes such as carburizing, nitrocarburizing and nitriding need an active atmosphere to supply carbon and/or nitrogen to the metal surface.

Controlled gas atmospheres in batch and continuous furnaces help achieve the desired surface finish, comply with increasingly strict specifications for part quality, improve strength and wear resistance, and reduce rework effort and reject costs. Ultimately, they enable heat treaters to meet the exceptionally high standards expected of metals today.

We have decades of experience in installing the gas supply systems and delivering the enabling gases for controlled atmospheres in heat treatment. In addition to special gas injection solutions, we offer furnace atmosphere control systems and optimized gas mixtures to improve process stability, precision and controllability. Our delivery systems are also designed to help you get the best return on valuable gases.

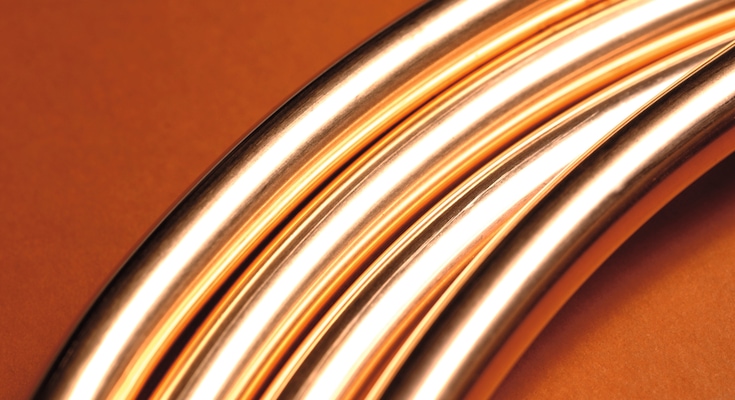

Examples of our field-proven controlled atmospheres include hydrogen/nitrogen mixtures for bright annealing of copper alloys, nitrogen/methanol for gas carburizing of steel, nitrogen/ammonia/carbon dioxide for gas nitrocarburizing, and hydrogen for furnace brazing. We also support many variants of these processes.

Discover how CARBOFLEX can improve carbon control for consistent result in carburizing, annealing and hardening

Inject your gases and gas blends at high speed to create homogeneous gas mixing and temperature uniformity in different furnaces

Explore the benefits of our CARBOTHAN nitrogen/methanol-based solution plus special gas lancing technology for hardening, carburizing, carbonitriding, annealing & sintering

Look forward to clean and bright product surfaces with our HYDROFLEX atmosphere control solution for annealing, sintering & brazing

Achieve consistent nitriding/nitrocarburizing results and improve resistance to wear, corrosion and fatigue with our special NITROFLEX atmospheres