Bright Annealing, Sintering & Brazing with HYDROFLEX

Protective Hydrogen/Inert Gas Atmospheres

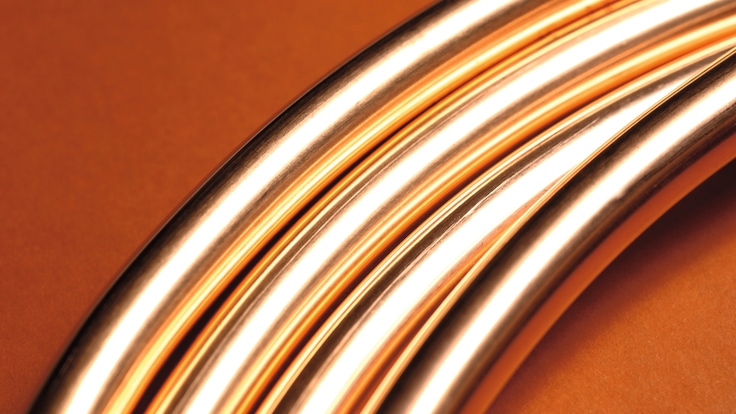

HYDROFLEX® atmosphere control solution for oxide-free heat treatment of copper alloys and stainless steel, in continuous or batch furnaces

Universal Solution for Oxide-free Heat Treatment

HYDROFLEX monitors the furnace atmosphere and determines the optimum ratio of hydrogen and nitrogen or argon to control surface reactions in your bright annealing process. While the inert gases nitrogen or argon maintain the furnace pressure as the carrier gas, the hydrogen serves to reduce surface oxides and prevent further oxidation. Thanks to advanced process control, the ratio of hydrogen to inert gas can be adjusted dynamically to create a perfect fit for each heat treatment challenge.

Benefits at a Glance:

- Precisely controlled atmosphere for clean and bright product surface

- Active control over process parameters with storage of process data history

- Full control over the supplied gas composition

- Reduced rework and rejection costs

- Automatic safety purging and safe hydrogen operation

Curious to discover more?

Contact us today and see how your heat treatment processes can benefit from an oxide-free hydrogen-based protective atmosphere

Contact Us